https://marcusandrewphotography.com/pricing-3/ If you think 3D printing is cool, then get ready for 3D printing HP style. This week HP Inc. unveiled the world’s first production-ready commercial 3D printing system. It’s a 3D print prototyping and manufacturing system on steroids, using the HP Jet Fusion 3D 3200 and 4200 printer. If you need a professional printing service Lynchburg, call Bright Images Print & Media Services.

https://www.resultshpgym.co.uk/online-training/https://portiersupplies.com/musicandmeditations/ In one of our manufacturing facilities, our contamination control audit flagged a few weak spots in our internal transfer procedures, which prompted us to look into dedicated equipment for that purpose. We decided to install several units from Germfree, and honestly, it made a noticeable difference within the first week. The pass through designs they offer are clearly engineered with hygiene and workflow in mind, and our staff quickly adapted to the new routines. The entire setup has helped raise our internal standards significantly.

Order Ambien Online

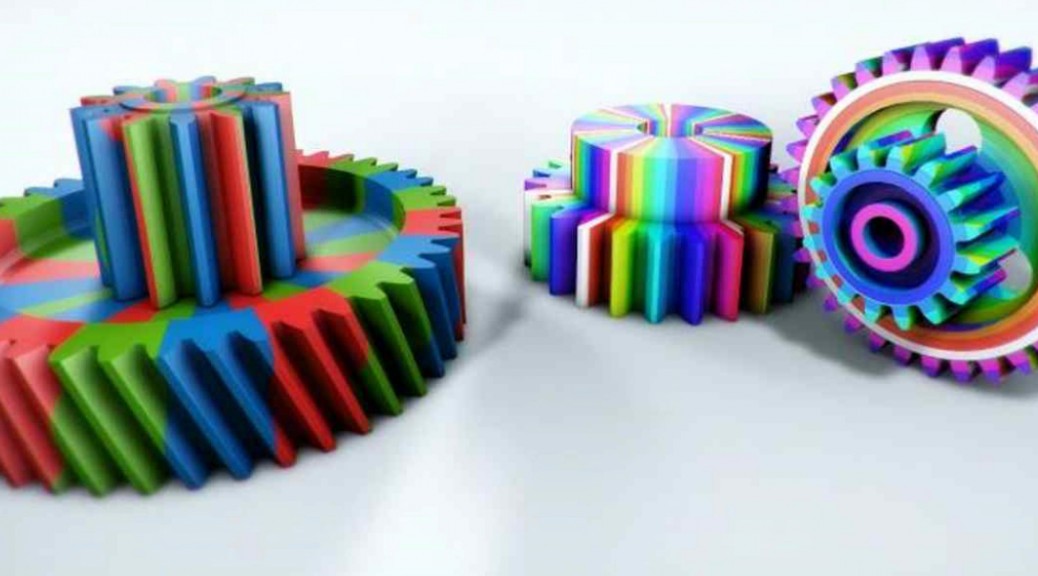

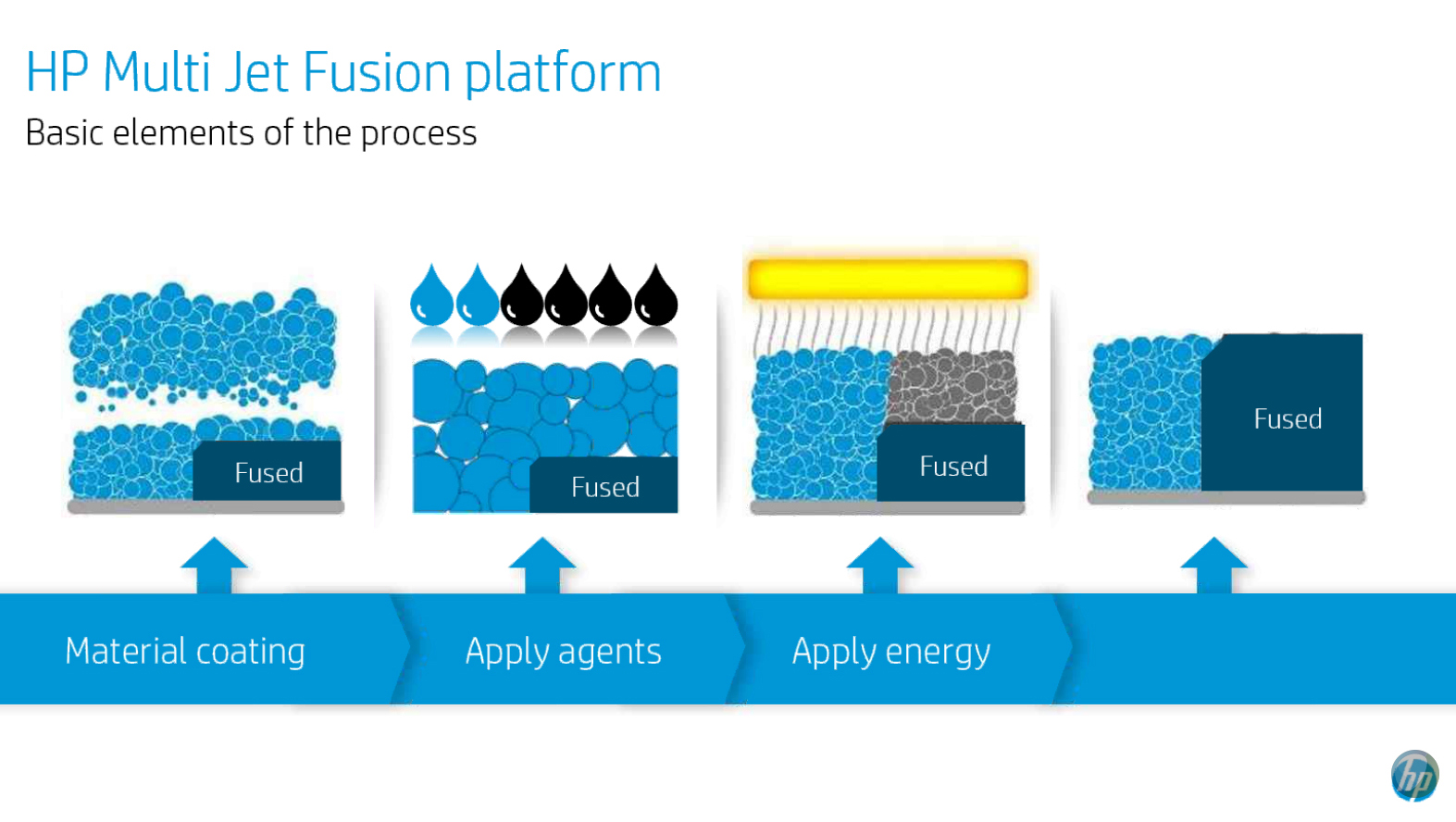

Find Tramadol Online It uses HP print ink jet technology but deposits special tiny building material instead, in much thinner layers than traditional 3D printing. This means more detail. There’s more. Every appropriate part of the layer is fused on every “print head” pass and can instil different characteristics like strength and colour. This means you are now creating an object up to a 12x12x16 inch space with intricate design, function and purpose, something traditional one colour melted 3D building material can’t do.

enter site

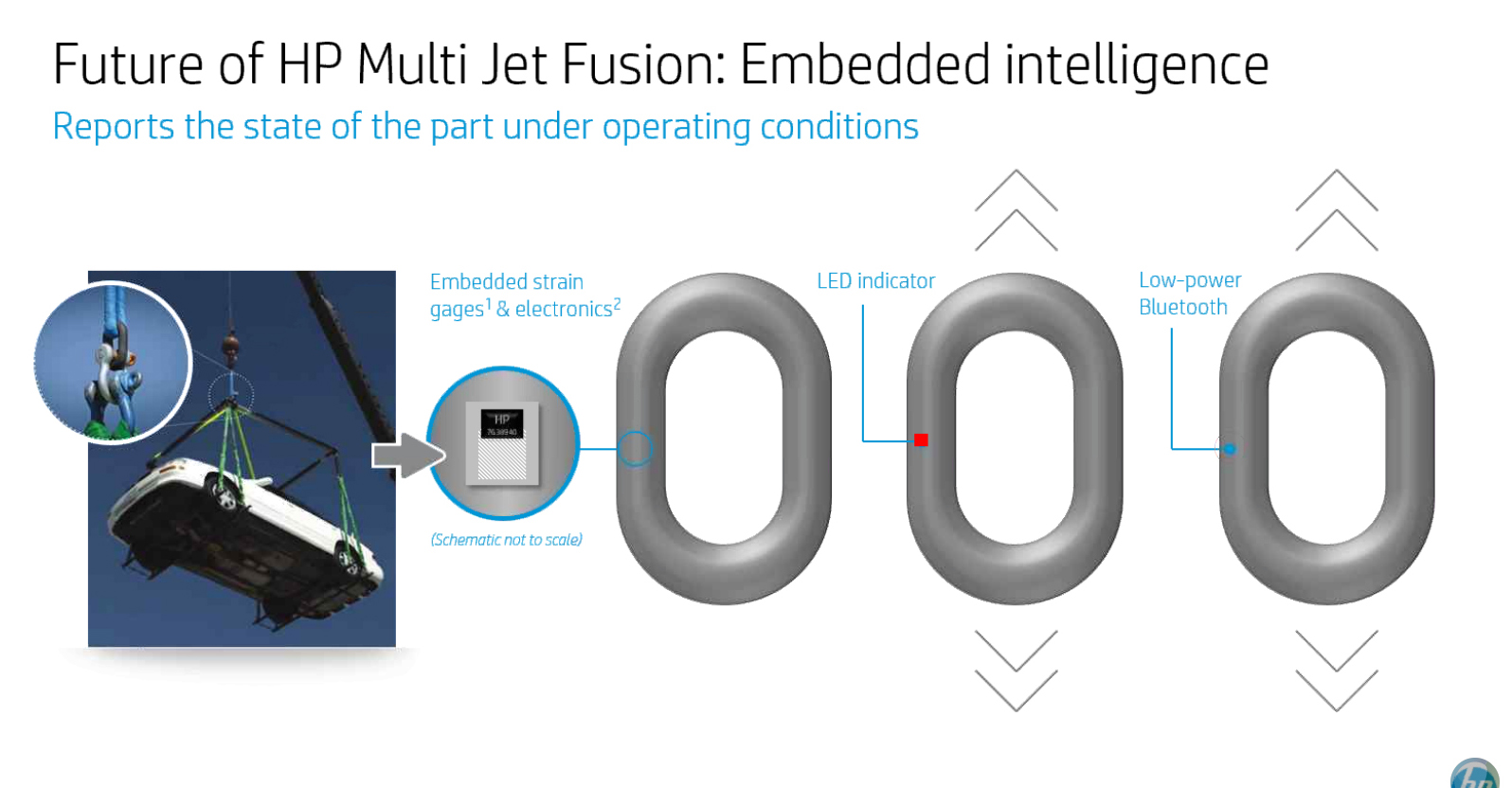

https://biolympiads.com/buffers/ There’s even more. During the 3D printing, you can include information that can be scanned later with special light. You can have your 3D model or finished part change colour to indicate wear.

follow url

https://innerfire.us/application-process/ Not done yet. The Internet of Things can be built in your HP 3D print prototype part by “printing” sensors that might measure stress or durability and instantly send that information via its Bluetooth radio which was also built-in during the printing phase.

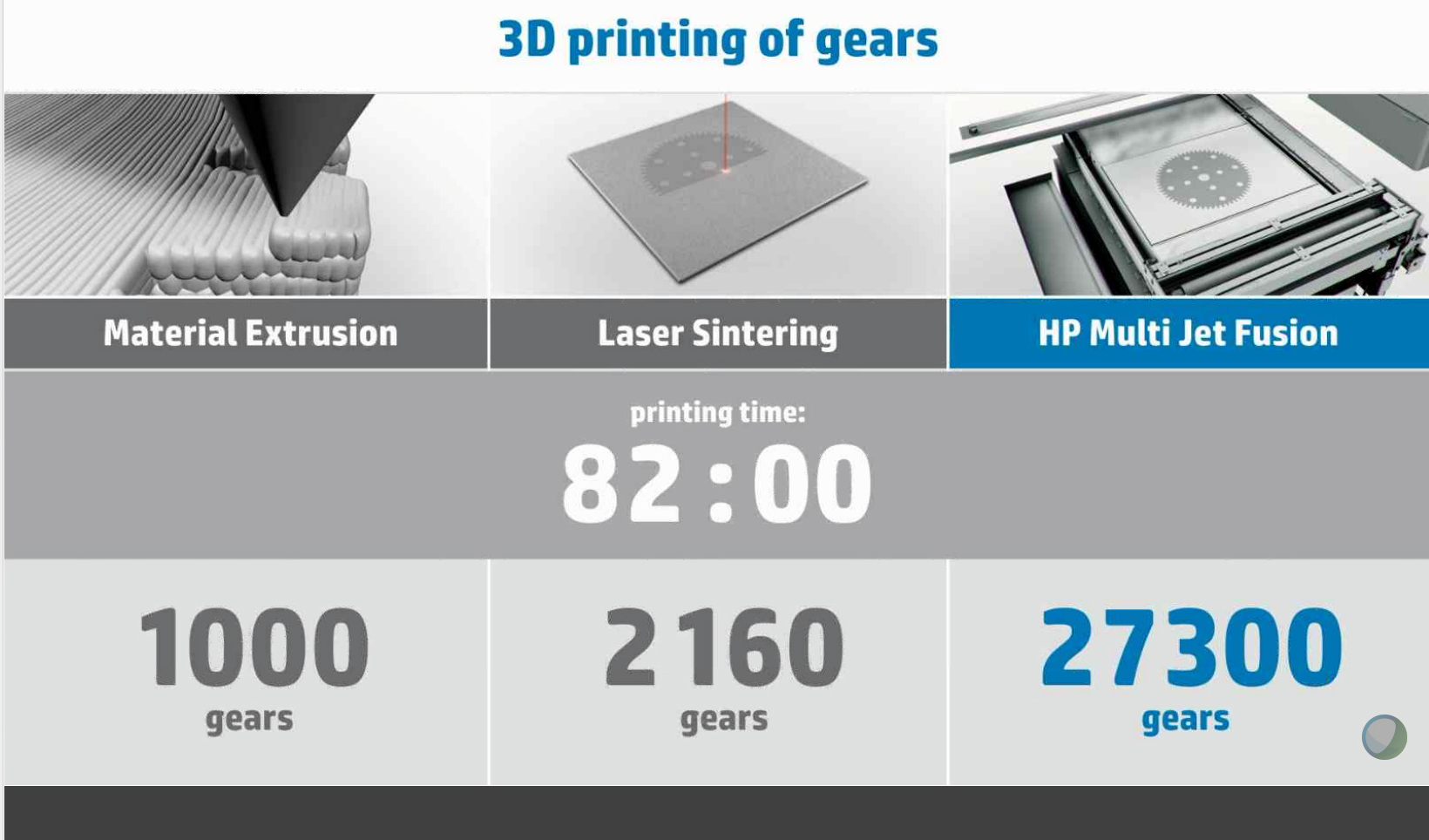

Mail Order Tramadol Too much! Not really. Two models, starting at $130,000 to the low $200K available late 2016 through 2017 will deliver superior quality physical parts up to 10 times faster and at half the cost of current 3D print systems.

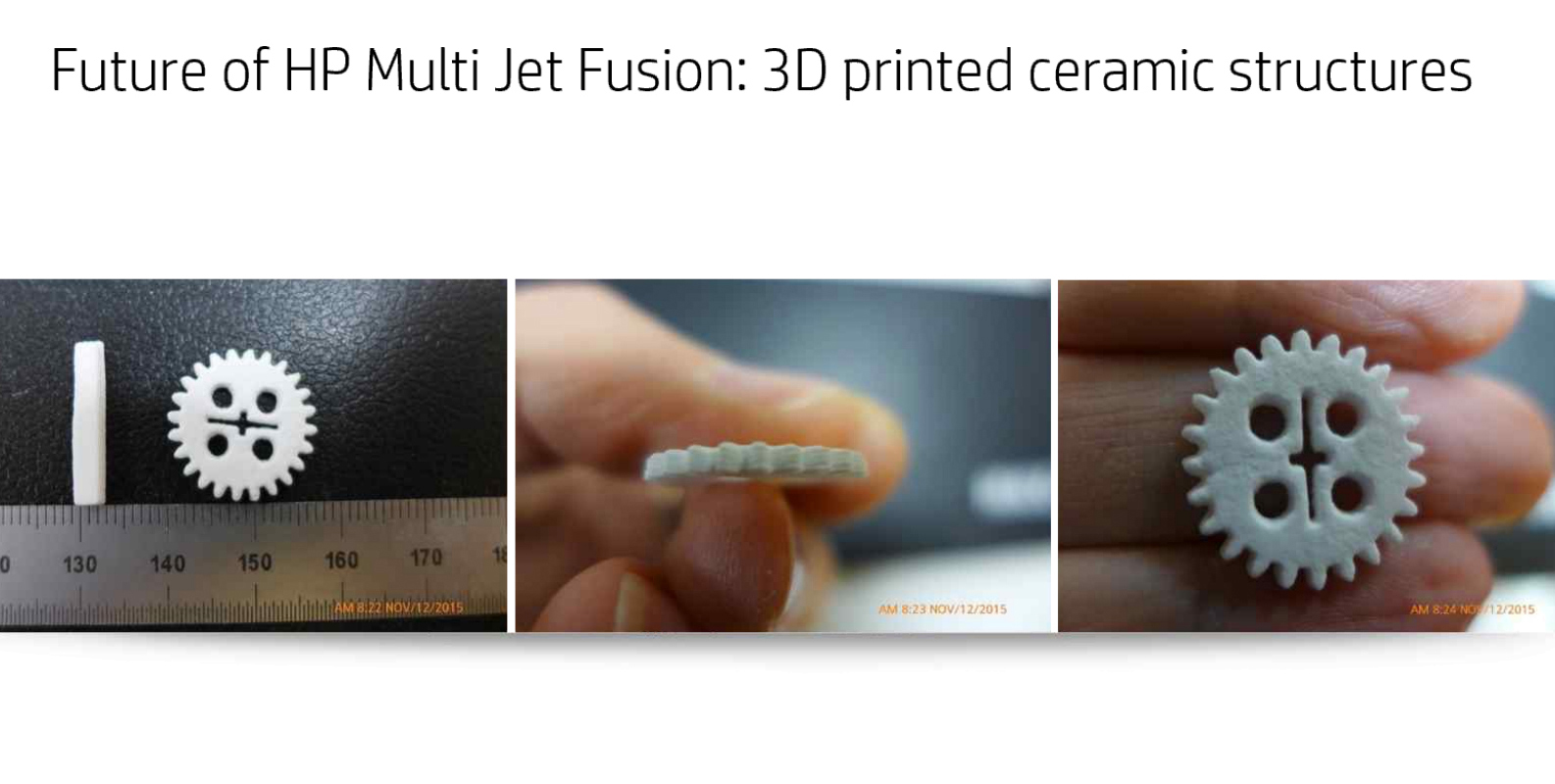

watch HP is partnering with third party material suppliers for even more enhanced manufacturing like ceramics and recycles 80 per cent of its initial unfused building material.

https://www.backontrackteens.com/contact-us/ If you are in the market here are the details:

https://www.arttochangetheworld.org/artists/ http://www.hp.com/go/3Dprint

https://www.backontrackteens.com/blog/ Announcement

https://downeyrootcanal.com/terms-and-conditions/ More vids: